Metalworking

Strength

1

1

YOUR SOLUTION

IS HERE

Cost reduction, prototype, and stable mass production through optimal design of processes and production methods.

Contact us to learn how we can help on your project.

We are good at efficiency and cost reduction through optimization of production methods and equipment layout.

Mass production of complex processing tends to increase costs, but we can achieve cost reduction and stable mass production by devising processes and production methods.

We are actively engaged in production automation using state-of-the-art machinery, equipment, robots, and always provide the best proposals possible.

2

2

RELY ON

US

Quality Guaranteed. High-precision quality assurance and continuity with new state-of-the-art equipment.

Every part that leaves our facility matters.

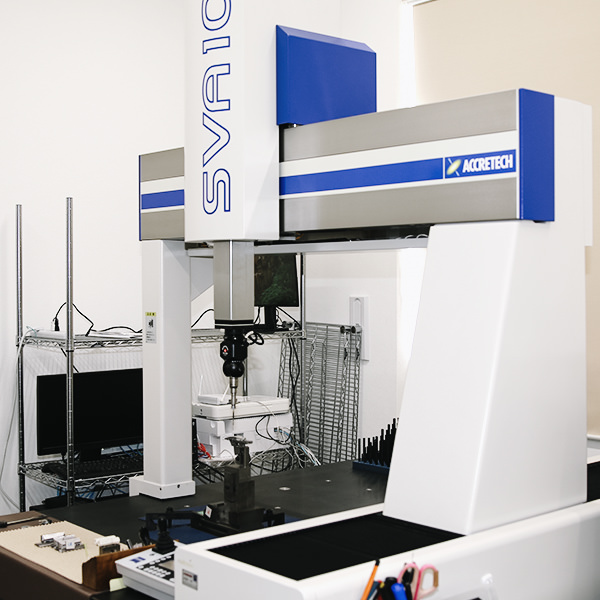

We use three-dimensional measuring instruments to efficiently perform high-precision inspections of products with complex shapes to ensure reliable quality.

Depending on the product, we also perform measurement using image measuring instruments, surface roughness meters, etc.

Our integrated response ensures that if a problem should occur, we will quickly identify the cause and resolve the essential and ongoing issues.

We are ISO 9001 certified.

3

3

LEAVE IT

TO US

Integrated Production. Delivered with heat treatment, surface treatment, and other necessary processing.

Receive it and you are ready to go.

Manufacturing metal parts requires a variety of highly specialized processes, including material selection and procurement, heat treatment, surface treatment, MIM processing, and precision sheet metal processing.

We utilize our network of partner companies to perform the various processes required by our customers before delivery.

Our integrated approach contributes to lower costs, shorter delivery times, and higher quality.

Piece of Work

- Rifle Parts

- Material: Nickel-chrome-molybdenum steel

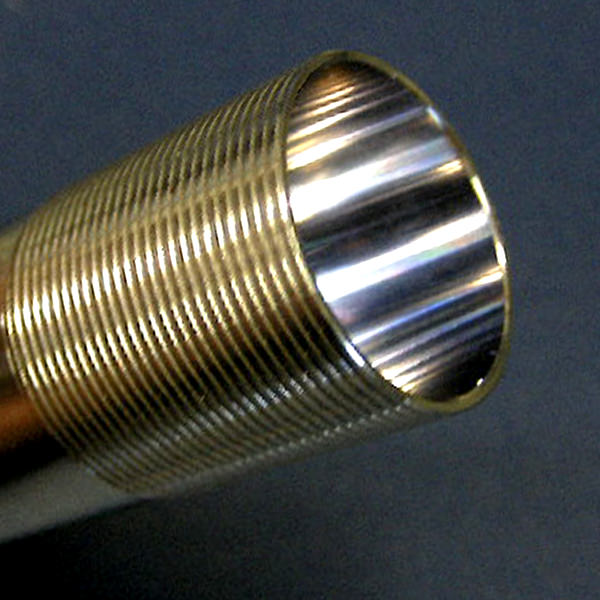

- Rifle Parts

- Material: Chrome-molybdenum steel

- Shotgun Parts

- Material: Chrome-molybdenum steel

- Shotgun Parts

- Material: Chrome-molybdenum steel, etc.

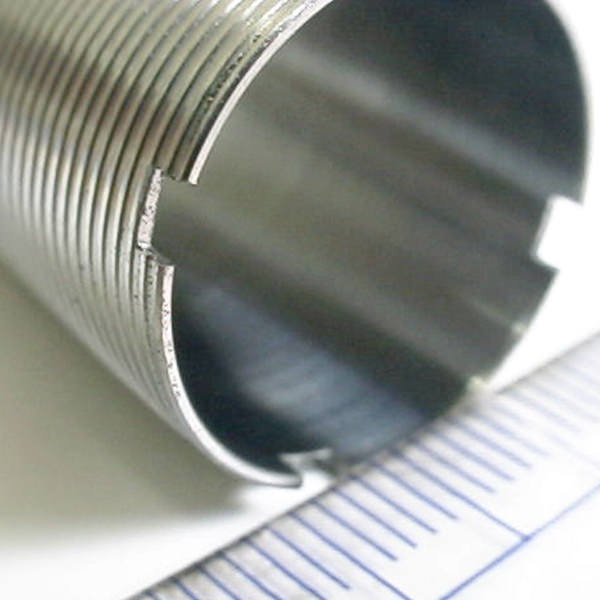

- Ultra-thin Wall Processing

- 0.15mm thick. Made of super high tensile strength material (Maraging steel). Realizes unbreakable strength despite its thinness.

- Mirror finish processing of inside diameter

- Seamless mirror finish processing of tapered inner diameter. Minimum wall thickness 0.15mm, quenching hardness HRC60-62, roundness accuracy within 10μ.

- Laser marking

- Laser engraving

- 3D Machining

- 3D high-speed MC machining by 3D surface

- Food plant parts

- Material: SUS304

- Automobile hydraulic parts

- Material: SUS316

- High pressure valve

- Material: Hastelloy

- Valve parts

- Material: Inconel

- Divine Mirror

- SUS630 Mirror surface TIN coating